Upload drawings, receive quote and technical feedback within 48 hrs.

Select production location, speed, quality control and shipping options.

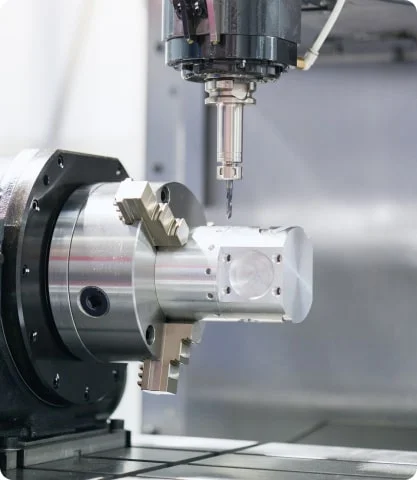

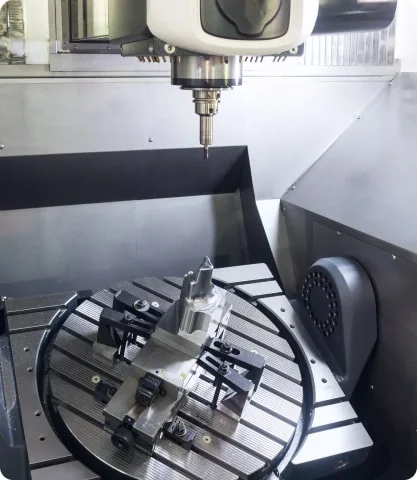

The most suitable manufacturer to produce your parts is selected and managed by Machinix supply chain team.

Each batch is inspected by our quality control team in our local inspection facility.

Parts are delivered by your selected shipping method.