Trusted by industry leaders in semi-conductors, robotics, medical devices, digital printing and more

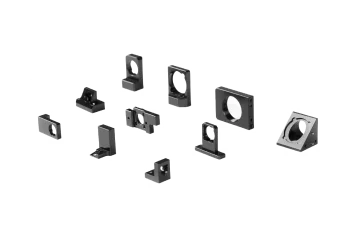

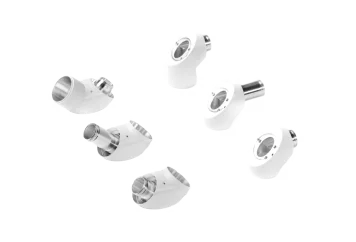

5-Axis machining

5-Axis machining

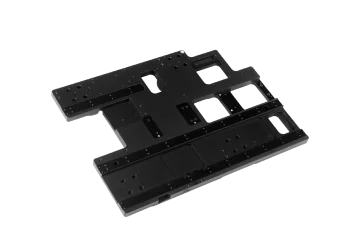

3-Axis machining

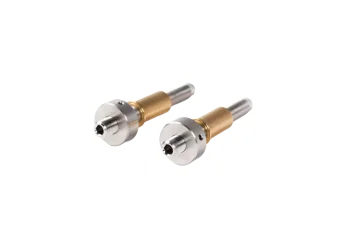

Swiss type turning

3-4 Axis machining

Turn-mill multitasking

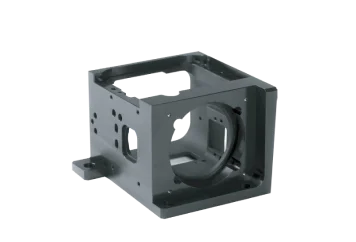

- Aluminum 6061-T651, 6082-T6, 5083-T6

- Black matt anodizing for low reflections

- Stainless steel 416, 304, 316, 17-4ph

- Electroless nickel plating for UHV

- Precision plates: C250, ACP5080, MIC 6

- Class 100 clean room cleaning

- Low thermal expansions alloys: Invar, RSA443

- +100 more materials and treatments

We pay high attention to

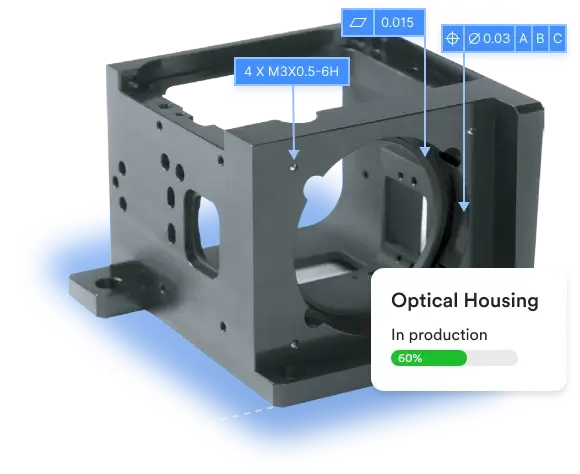

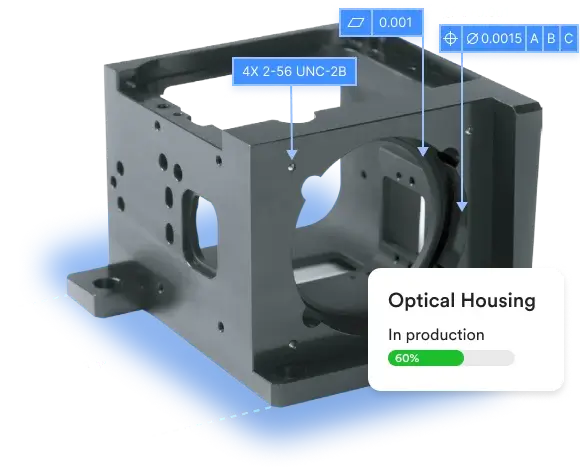

- Implementation of optomechanical design intent in the production drawing

- Positioning of optical seating areas and mating surfaces

- Selecting the optimal manufacturing process for each component

- Achieving a uniform coating, with careful placement of coating clamping area

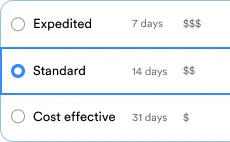

Produce locally or overseas at three speeds: expedite, standard or cost effective

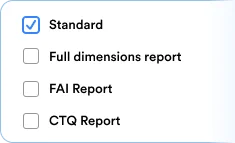

Choose the reports you need to fulfill your organization and industry requirements

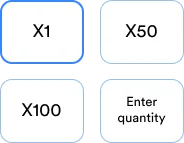

Order the exact quantity you need. From prototype to mass production. No MOQ!

Choose your preferred shipping method - air, sea, or with your courier

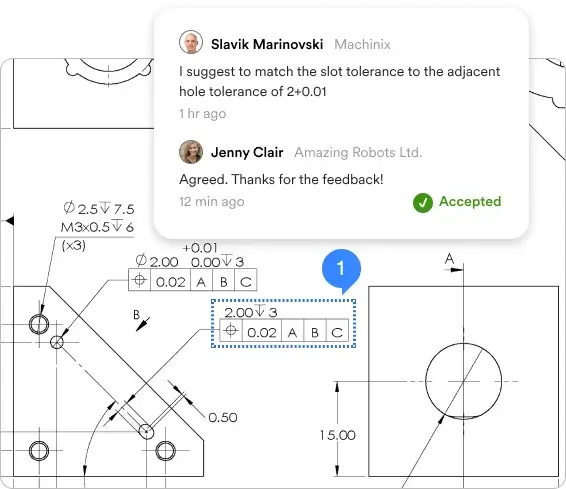

Our feedback aims to:

- Improve manufacturability, reduce cost and shorten lead time

- Recognize and highlight incorrect or conflicted tolerances, materials and coatings

- Improve GD&T Implementation

Upload drawings, receive quote and technical feedback within 48 hrs.

Select production location, speed, quality control and shipping options.

The most suitable manufacturer to produce your parts is selected and managed by Machinix supply chain team.

Each batch is inspected by our quality control team in our local inspection facility.

Parts are delivered by your selected shipping method.

Parts Delivered

Quality rate

Years of Experience

Machinix Experts